Visit our Blog and Subscribe!

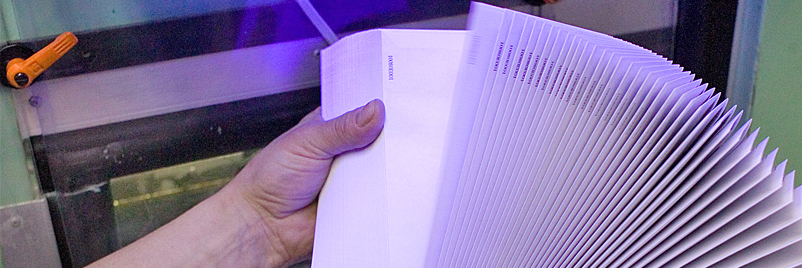

As a wholesale supplier, we understand that our customers prefer to market our products with their own brand. To do so is simple:

If you or your customers intend on printing on your labels after they're manufactured, it's important to take the type of imprinting and face stock into consideration. Always match the correct face stock with technology to insure successful imprinting. Specific face stocks are available to be used with these imprinting methods:

Lasers are used to image a charged rotating photoconductive drum. The charge in the imaged area attracts toner powder during the drum rotation. High temperatures fuse the toner to the face stock.

| Strengths | Limitations | Compatible Label Stocks |

|

|

|

Transfers heat activated ink from a ribbon to a specially coated paper (thermal transfer stock). Always match ribbon to face stock.

| Strengths | Limitations | Compatible Label Stocks |

|

|

|

A non impact, plateless, process that prints from digital data and uses jets of very fine ink droplets fired at the substrate to form the same or variable information images onto paper or other substrate without a press. There are two main types of ink jet devices: continuous and drop on demand.

| Strengths | Limitations | Compatible Label Stocks |

|

|

|

Computer controlled print heads contain small resistive elements that heat the label surface. A chemical reaction occurs in the face stock, which turns the heated area black.

| Strengths | Limitations | Compatible Label Stocks |

|

|

|

Labels printed with a computer-controlled print head produce a chain of dots in a pattern that forms a printed character. Dots are formed when a series of pins strike an inked ribbon. When the ink is transferred to a product, it dries by absorption or evaporation.

| Strengths | Limitations | Compatible Label Stocks |

|

|

|