Visit our Blog and Subscribe!

As a wholesale supplier, we understand that our customers prefer to market our products with their own brand. To do so is simple:

Many people feel that a pressure sensitive label can be applied successfully to everything. Not true! There are some surfaces to which pressure sensitive labels will not adhere at all. The key to success in any label application is to test the face material and adhesive prior to the label order being placed. This simple process will prevent problems from occurring later. Three important things to consider:

The performance of adhesives is dependent on three measurable factors:

Tack

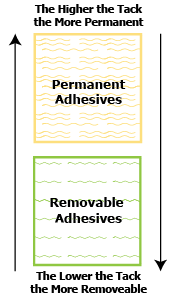

TackTack defines the degree to which an adhesive will stick to a surface on first contact. Tack allows an adhesive on a pressure sensitive label to “wet” a surface and form an appropriate bond. The tack increases on smooth or heated surfaces (high surface energy) and decreases on rough or cold surfaces (low surface energy). See chart below. Tack can be laboratory tested by measuring the amount of force needed to peel it away from a substrate.

Adhesive performance is highly dependent on its contact with a surface–it should be applied with firm pressure on a dry surface that is free of contaminates.

Specific adhesion is an adhesive’s ability to stick/adhere to a surface after it has been allowed to fully set. A minimum of 24 hours, preferably 72, should be allowed for the adhesives to set before determining whether the product has the proper amount of adhesion. An adhesive may bond well to one surface such as glass, but poorly on another such as polyethylene. Adhesion qualities can be tested by measuring the amount of force needed to peel away the label from various surfaces under specific bonding and conditioning circumstances.

The internal strength of an adhesive is its cohesiveness. To prevent a label from splitting when removed from a surface, the cohesive strength has to be greater than the specific adhesion. One method of measuring the cohesive strength of a label adhesive is by vertically bonding a label sample to a test bar. A weight is then attached to the sample. The amount of time that elapses before the sample pulls free of the bar is a measure of shear strength.