Visit our Blog and Subscribe!

As a wholesale supplier, we understand that our customers prefer to market our products with their own brand. To do so is simple:

When it comes to envelope design, it's best to understand and consider each of it's parts. This will help you dial in on the perfect stock product or custom create an envelope to fit your needs!

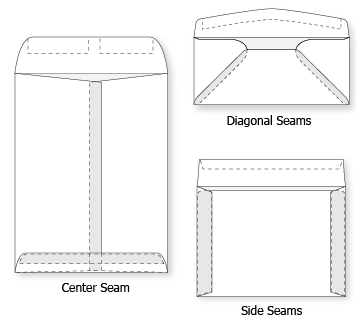

Envelope seams are typically permanently sealed for durability.

Envelope seams are typically permanently sealed for durability.

Variations include:

Center Seams – Most commonly used on coin and catalog envelopes.

Diagonal Seams – Used on commercials and pointed flap baronials.

Side Seams – Provide a large area for printing on the back, as in reverse face, collection and booklet envelopes.

Weld Seams – Eliminate die cutting and can be produced to permit insertion and trimming in a magazine. The envelope’s pocket size is determined by the distance between the internal gum lines.

Bottom and side flaps form an envelope’s body and are usually permanently bonded in the folding operation. Seal flaps vary widely among envelopes styles. The most common flap shapes are:

|

Bankers – Used on commercial style envelopes to provide additional sealing area. |  |

Extension – Constructed without a flap, but rather with an extension of the face, neither gummed nor scored, to assist with material insertion. | |

|

Flip-Stik – Latex adhesive is applied on two flaps and separated until sealing. |

|

Hub – Used on catalogs. |

|

|

Cheese Blades – Used on booklets and machine insertables. |

|

Monarch – Used on #7-1/2 envelope flaps. |

|

|

Pointed – Used on most baronials. |

|

Round – Used on some small coin, drug and pay envelopes. |

|

|

Scalloped – Used on our Church Offering envelopes. |

|

Square – Used on announcements and some booklets. |

|

|

Standard Commercial Flap – Used on commercials. |

|

Wallet – Provide additional area for printing on both the back and seal flap; used on dual purpose, some commercials, collections, and order-form envelopes. |